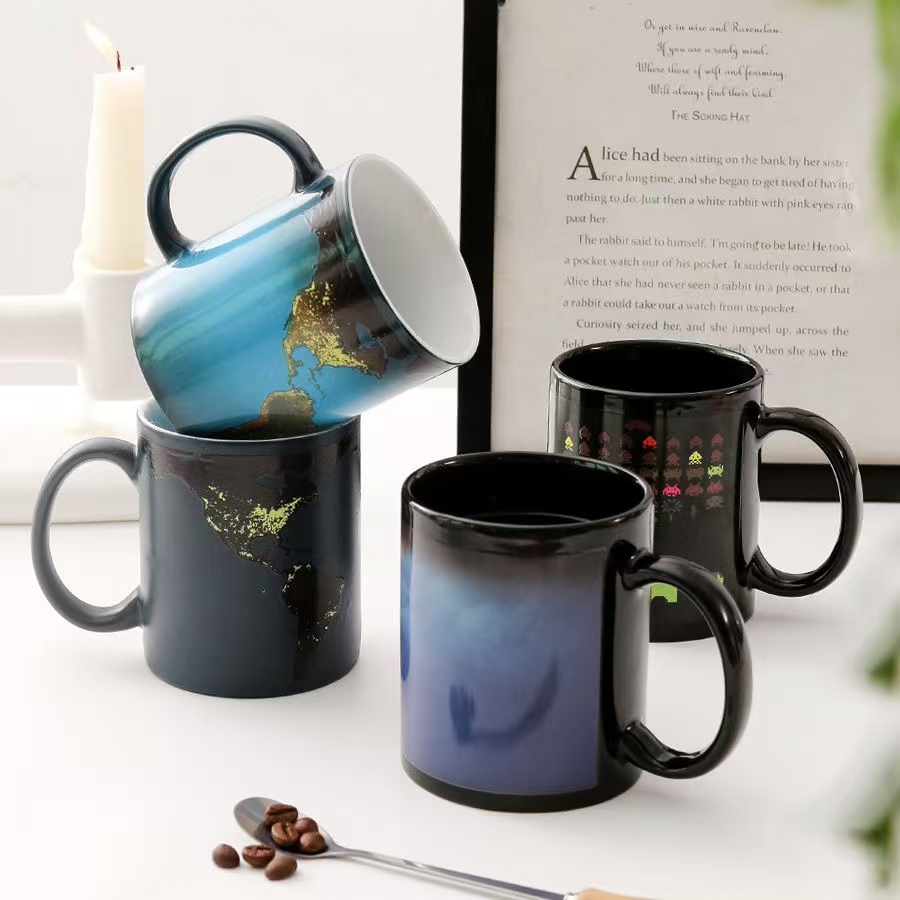

Color changing mug

The color-changing mug, also known as the magic mug, injects hot or cold water into the mug cup. The color of the mug body will change. The color before the color change is black, red, yellow, green, blue, brown, purple. Light blue, light yellow, light green, reddish, pale purple, pink, etc.

Including the dot effect, it can be designed as a surface layer of the color changing mug. Ceramic color-changing mugs and glass-changing mugs are divided into thermochromic and cold discoloration and discoloration in water.

Principle of color change

When the temperature of the thermochromic mug is above 40 °C, the color changes. When the temperature of the cold color-changing mug is below 20 °C, the color changes, and the water color is still not popular. Their principle is: the temperature sensitive material is printed on the body of the mug, the material used is heat sensitive material, high temperature resistance 320 ° C, non-toxic, lead-free, chromium-free can meet European standards. According to the design of the design draft, film, plate, print, dry, roast, and then package.

Printing process

Now the material mark cup is processed into a color-changing mug, basically one of three methods: 1, direct printing; 2, water transfer; 3, thermal transfer. These three processes are processed.

1. Direct printing:

Cold color mug with ice water (ice drink)

Cold color mug with ice water (ice drink)

It refers to printing directly on the Mark Cup with a roller printing machine. This technology is technically difficult. The general factory can only print one to three colors. If you encounter high requirements for the position, there is nothing you can do with the color, but the factory has strength. It can overprint up to 20 colors without walking. This technology is only suitable for small batch production and is very inefficient. Only color blocks can be printed, and it is very difficult to print photos.

2, water transfer: is printed on the water transfer paper with a printing machine, so that you can print a rich color, the same can also be large quantities

Production, but the environmental requirements are relatively high, the printing environment is required to be constant temperature, constant humidity, in order to ensure the printing accuracy, the printed water transfer paper is placed in the water, the pattern is separated from the paper, and the pattern is transferred to the mark cup to bake the finished product. The following Christmas color-changing mugs belong to this process.

3, thermal transfer: the same as the water transfer printing process, the printed thermal transfer paper is transferred to the mug by the machine heating and pressure, water transfer production of color-changing mug, when the transfer of the pattern Relying on manual operation, and thermal transfer is by machine

Automated processing, so a modern color-changing mug factory, with color-changing pigment production line, automatic printing production line and fully automatic thermal transfer decal production line, is the strongest manifestation of competitive strength.

Precautions

The use of color-changing mugs requires attention:

(1) Do not use in high temperature places such as microwave/dishwasher/disinfection cabinet.

(2) It is not suitable to expose to sunlight.

(3) It is not suitable to soak in water.

(4) Do not scrape/scratch the surface of the body of the mug with a hard object, otherwise the image of the mug body will fall off.